Pharmaceutical Dissolution Testing

In the pharmaceutical industry, dissolution testing is a vital analytical technique used to evaluate the rate of drug released from a dosage form. When utilizing a dissolution system, the amount of drug that is released under standard conditions is measured, simulating the drug product’s behavior in the body after administration. The overall purpose of dissolution testing is to ensure that a drug product consistently and reproducibly releases the active pharmaceutical ingredient (API) as intended. The rate of dissolution can significantly impact the drug’s bioavailability and therapeutic efficacy, therefore, establishing dissolution specifications is immensely important in supporting quality control and regulatory compliance.

Through the lifecycle of a pharmaceutical drug product, dissolution testing is an essential part of drug development, formulation optimization, and quality control. The data obtained from dissolution testing helps determine critical parameters such as the time required for a specified percentage of the drug to dissolve (dissolution profile), dissolution efficiency, and dissolution rate. These parameters are compared against established dissolution specifications or regulatory guidelines to ensure that the drug product meets the required standards of quality and performance.

Dissolution Apparatus Types

There are several types of dissolution systems available, each designed to accommodate different dosage forms and provide specific testing conditions. At CMC Pharma, we focus on both immediate-release and controlled-release drug products so our labs are suited with the appropriate instruments to effectively measure the dissolution of drugs from these varying dosage forms.

For immediate-release dosage forms such as tablets and capsules, we utilize USP Apparatus II, commonly referred to as a Paddle Apparatus. This system includes a paddle, which is lowered into the dissolution vessel and rotated at a specific speed. The paddle provides a gentle, uniform agitation to measure release.

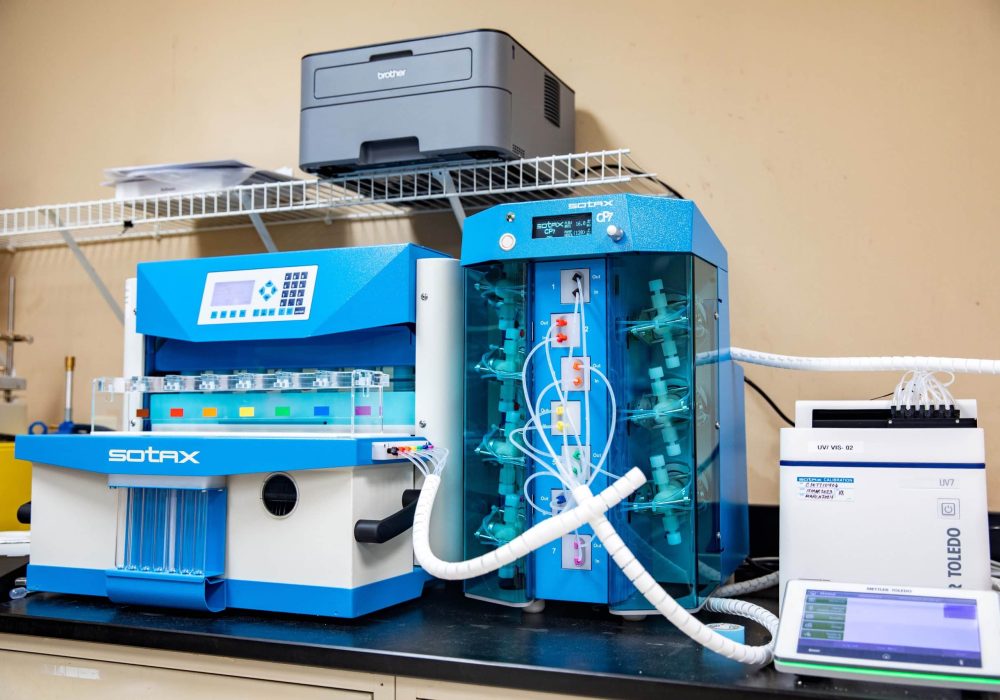

We also have Sotax USP Dissolution Apparatus IV. This apparatus is specifically designed to measure controlled release and allows us to test more complex dosage forms including microspheres, injectable suspensions, transdermal patches, medical devices, implants, and more. This instrument is equipped with a continuous flow-through cell system, allowing drug permeability and membrane characteristics to be studied. Our instrument also has an online UV detector to measure drug concentrations in the elution media that can be sampled for offline HPLC analysis.

While other Dissolution Apparatus types exist, CMC Pharma utilizes these two systems as they most closely align with the drug product development programs we focus on. The addition of Sotax USP Apparatus IV enables us to further assist clients with complex drug product development programs and eliminates the need to outsource to other labs. Our extensive experience in designing and executing appropriate formulation and analytical development studies for early-phase products creates a strategic path to move your product into the clinic with the ultimate goal of product approval

The Importance of Dissolution Testing

At CMC Pharma, we understand the crucial role of pharmaceutical dissolution testing in ensuring the quality and efficacy of drug products. Dissolution testing plays a vital role in the development, manufacturing, and regulatory approval of pharmaceuticals. By evaluating the rate and extent of drug release from dosage forms, dissolution testing provides valuable insights into a drug’s bioavailability and therapeutic effectiveness. Our facilities employ industry-standard apparatus, including USP Apparatus 2 and 4, to accurately simulate drug release in the body. This allows us to assess batch-to-batch consistency, optimize formulation designs, and ensure regulatory compliance. With our expertise in dissolution testing, we support our clients in achieving robust drug development, quality control, and successful regulatory submissions.

Dissolution testing is not just a regulatory requirement; it is a fundamental tool for maintaining the highest standards of pharmaceutical quality. At CMC Pharma, we recognize that accurate and reliable dissolution testing is critical for assessing the performance and effectiveness of various dosage forms, including immediate-release and controlled-release. Our team of experienced scientists utilizes dissolution testing to evaluate critical factors, such as formulation design, excipient selection, and manufacturing processes, to ensure optimal drug release profiles. By conducting rigorous dissolution testing, we help our clients identify potential formulation or process-related issues early on, enabling timely adjustments and minimizing costly delays in drug development. With our commitment to excellence, CMC Pharma is your trusted partner in achieving exceptional dissolution testing results and ensuring the quality and efficacy of your pharmaceutical products.

Contact Us Today to accelerate your drug product development program!

Together, we can achieve exceptional dissolution testing results and ensure the quality and efficacy of your pharmaceutical products.

Send us a message or give us a call at 440-485-1734